Application Fields

We offer solutions in a wide variety of fields, such as:

Medical

In just a few years, BARBIER-EBELMANN has become a preferred partner in the medical field. We supply surgical saw blades that meet demanding specifications.

We perform maintenance on stamping tools used in prosthesis production.

We also produce mechanical parts that are then assembled into operating room equipment.

Material Conformity by the Factory and specific treatments certificates have become standard practice.

Aeronautics

With our in-house workshop and access to virtually all material removal technologies, we can offer you high-level services with complete autonomy.

Our participatory management approach allows us to anticipate most difficulties from the initial assessment of your specific requirements.

We can provide you with the parts along with supporting documentation, such as:

• material conformity certificate

• dimensional specifications

• dimensional conformity certificate

• etc.

Luxury

Having honed our skills in demanding sectors such as medical and aerospace, we naturally gravitated towards applying our expertise to the luxury market.

Using our micro-cutting laser, we have already supplied renowned brands in the world of Swiss watchmaking and French luxury. We also work in the eyewear industry.

Pneumatic

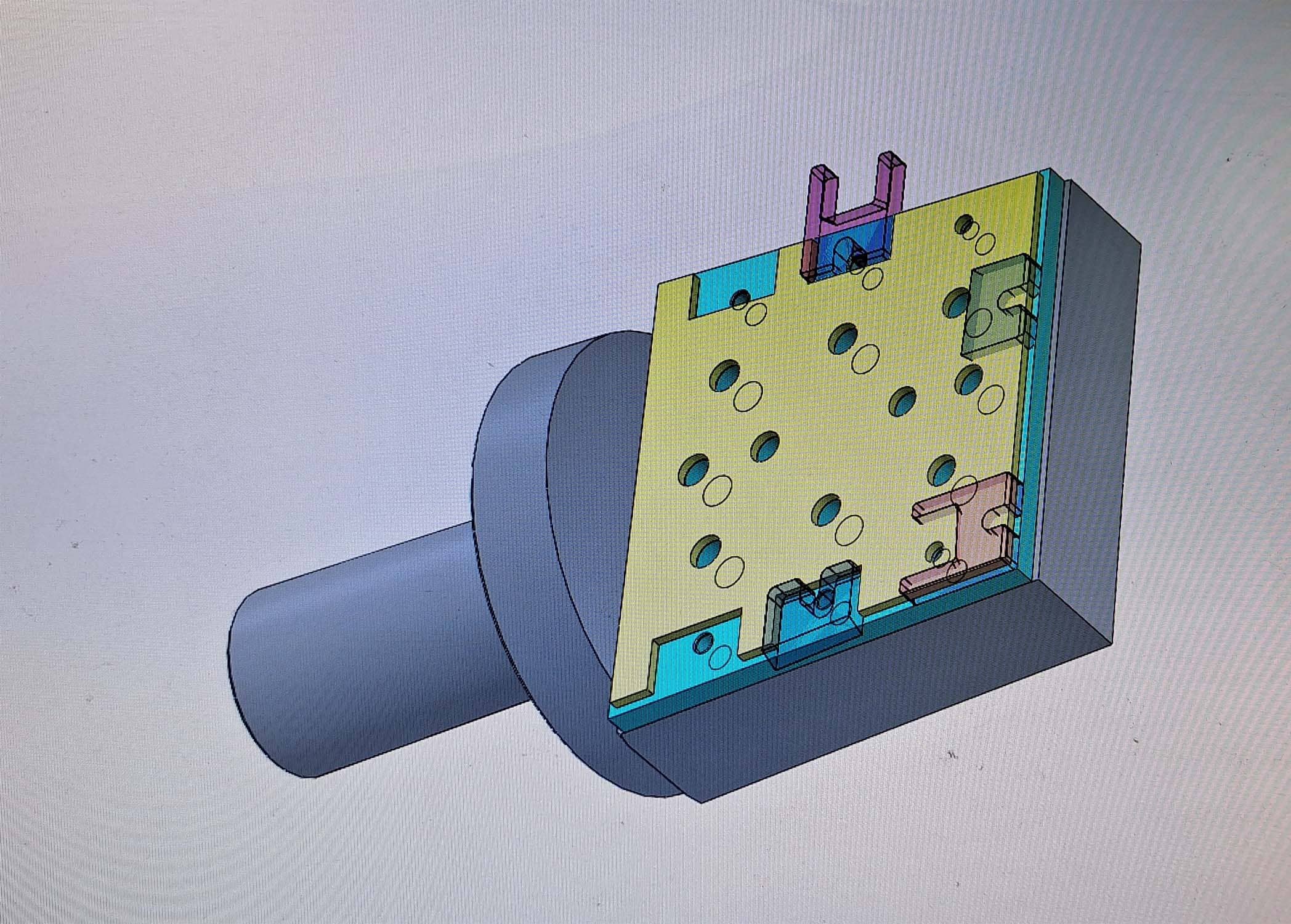

Machining a pneumatic mold component requires mastery of CAD and CAM software tools.

The specific aluminum alloy necessitates a rigorous and tailored machining methodology. Nothing can be left to chance, neither the constraints and requirements inherent to cutting tools, nor lubrication, nor expansion.

Petroleum Industry

BARBIER-EBELMANN has developed numerous hard metal machining techniques.

Tungsten carbide is one of them. We know how to machine this material before sintering to obtain complex shapes that would be impossible or prohibitively expensive after sintering. After sintering, only the guide surfaces need to be ground.

These parts are components of pumps used to convey drilling mud for analysis, in order to optimize the forces applied to the drill bit.

They were machined using the method described above.

Special projects

For a textile company, a part used to guide threads requires high abrasion resistance. It is manufactured using two different production processes (laser cutting, etc.).

For a leading company in its field, a copper alloy part serves as shielding for a specific connector. The part is obtained by laser micro-cutting, then deformed and assembled by electric welding.

For a company in the automotive field, a copper and tungsten electrode is obtained by machining the copper and roughing the tungsten with brazing, then finishing with wire electro-erosion and surface grinding.

Our technical capabilities

Our workshop has almost all material removal technologies, which allows us to offer the production of complex parts in very diverse materials.

Supplier

For the material of your choice and for heat and surface treatment processes.

Our team

Skills and experience to meet the requirements.

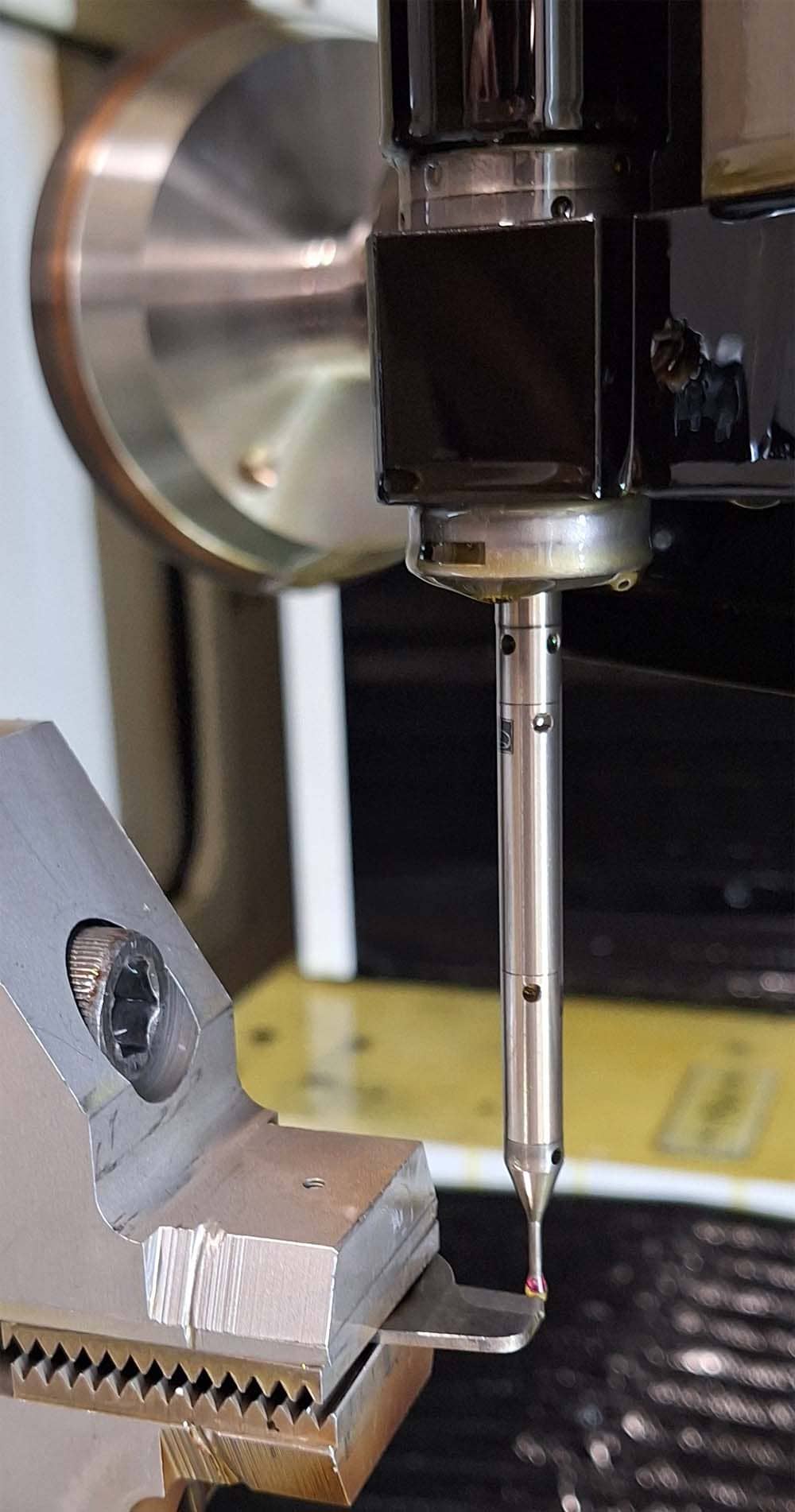

EDM

Wire or die-sinking for complex and precise shapes in all types of materials..

Quality

The concern for a quality service with the possibility of control reports and material monitoring by CCPU.

CAD/CAM

CAD for feasibility reviews and co-design. CAM for complex machining.

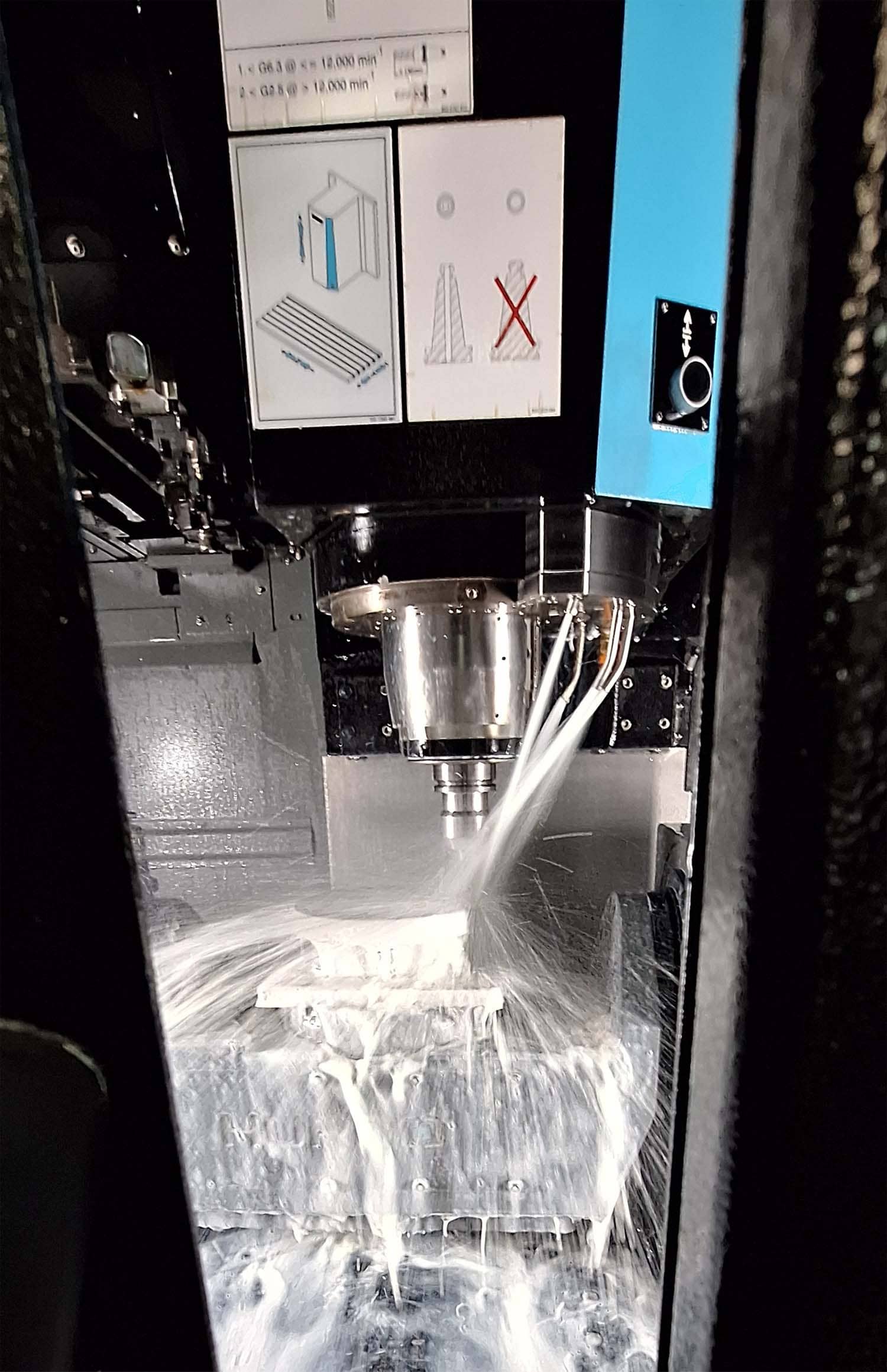

Milling

From 3 to 5 continuous axes for complex designs.

Laser

Micro-cutting in thicknesses less than 5mm depending on the material.

Surface and cylindrical grinding

Precision surface and cylindrical grinding for components made primarily from hard materials.

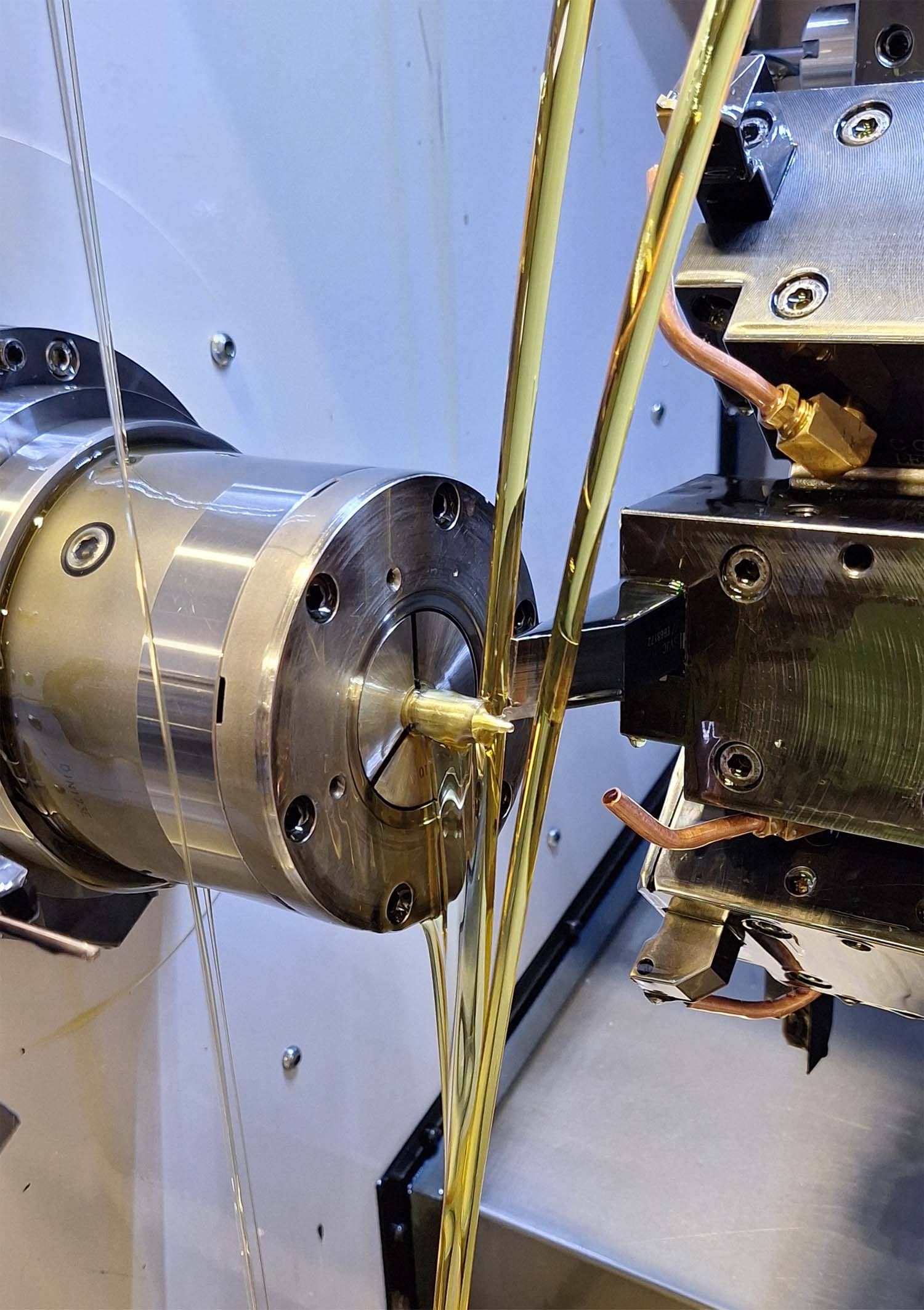

Turning

From conventional machining to multi-axis and multi-spindle systems.